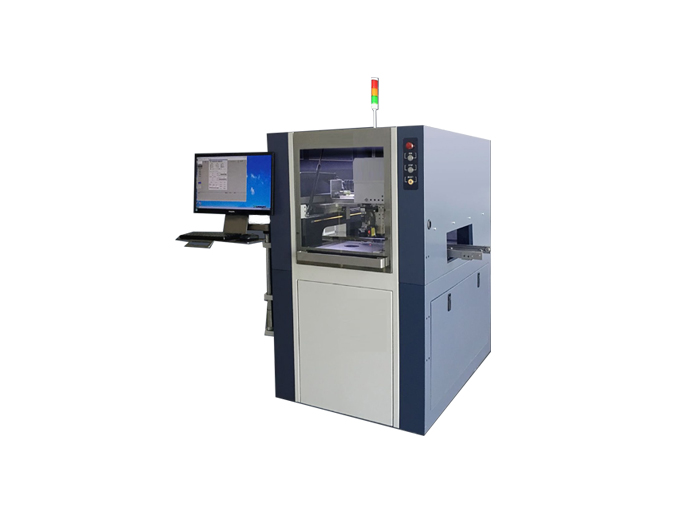

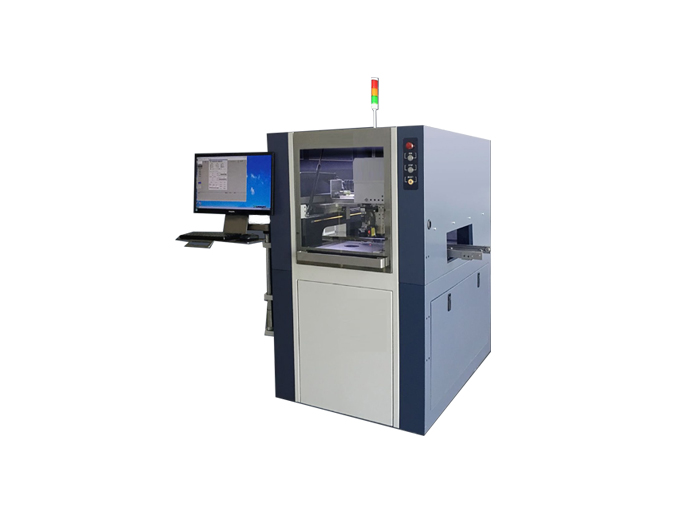

Why manual valve is installed in visual LED dispensing machi

作者:admin 日期:2017-10-16 18:00 浏览:

Visual dispenser is an important auxiliary tool now produces LED related products, mainly the implementation of the LED lamp dispensing package material bonding work, have a visual positioning system detected at any time, so in the daily work of dispensing can achieve very good results, is a manual valve control valve fluid through the valve installation manual visual LED dispensing the machine is better able to complete dispensing work.

The manual valve can control the fluid motion in the visual LED dispensing machine, this is the use of manual control to achieve quantitative glue control, manual valves to achieve the fluid diversion, regulation, diversion and other related operations, comprehensive wide and good operability. Manually control the biggest advantage is that the operator can according to their own needs to control, control effect is better than the automatic control valve through the visual, transmission speed, so the better applicability, but not so easy as automatic.

The manual valve emergency shutdown can be the glue, glue will sometimes change during normal use, with instant glue as an example, when the instant glue into the dispenser if unable to maintain its stability, will begin to cure in the flow process, blocking if the operator found problems not timely stop will cause the dispensing valve this is relatively rare, but may also occur, using manual valve can play the role of emergency shutdown glue flow, the instability of glue will abandon so as not to affect the normal use.

The manual valve durability common dispensing machine is very long, can long withstand all kinds of corrosive substances and qualitative change, and the highest working pressure of 1000MPA, temperature and applied widely, the valve is an important visual LED dispensing machine need to be configured.