The way of cleaning and maintaining the three axis glue mach

作者:点胶技术分析 日期:2018-03-20 14:52 浏览:

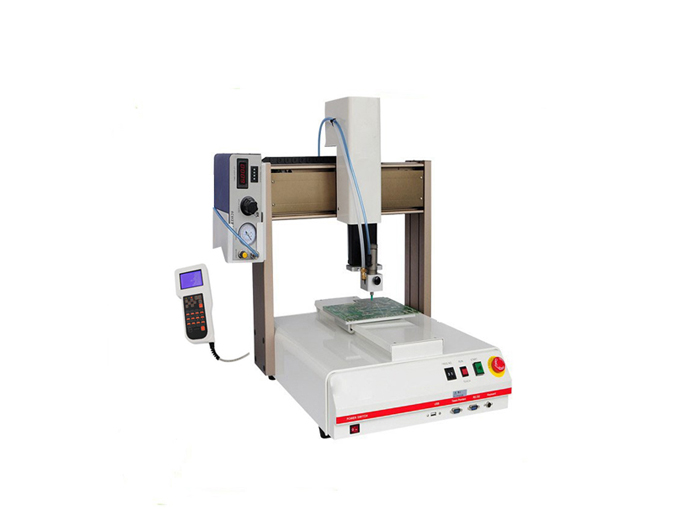

The LED lamp is very common in major shopping malls are bought, but the lamp is very difficult when dispensing, dispensing tube Led three axis dispenser for dispensing, dispensing machine with three axis work efficiency, good quality, are used in many places, but no matter when not use maintenance.

Led tube three axis dispensing machine must be regularly maintained, in the dispensing of the machine after the heat treatment, because the three axis dispensing machine overheating will lead to low efficiency, or directly burning, heat after check to check valves, check the dispensing valve is damaged, clean up on the top of the needle type dispensing valve, the use of cleaning special tools for a thorough cleaning of the dispensing valve, because no cleaning would lead to residue of chemical reaction on other glue, corrosion or blockage of dispensing valve.

After cleaning the dispensing needle, the process of cleaning the dispensing valve is still done with a special cleaning tool. In the process of cleaning, we should check whether the glue needle is blocked or not, even if it is blocked.

The dispensing machine is generally not a problem, a lot of the dispensing operation in the production process, ensure the service life of each part, because of the need of precision items, so the three axis dispensing machine each axis of the action will be recorded and operation, and the dispensing controller will ensure operation. The action of the controller is the internal standard, high precision processor, in order to ensure zero error, use the C language to make the control of each axis, to ensure the quality and effect of dispensing.